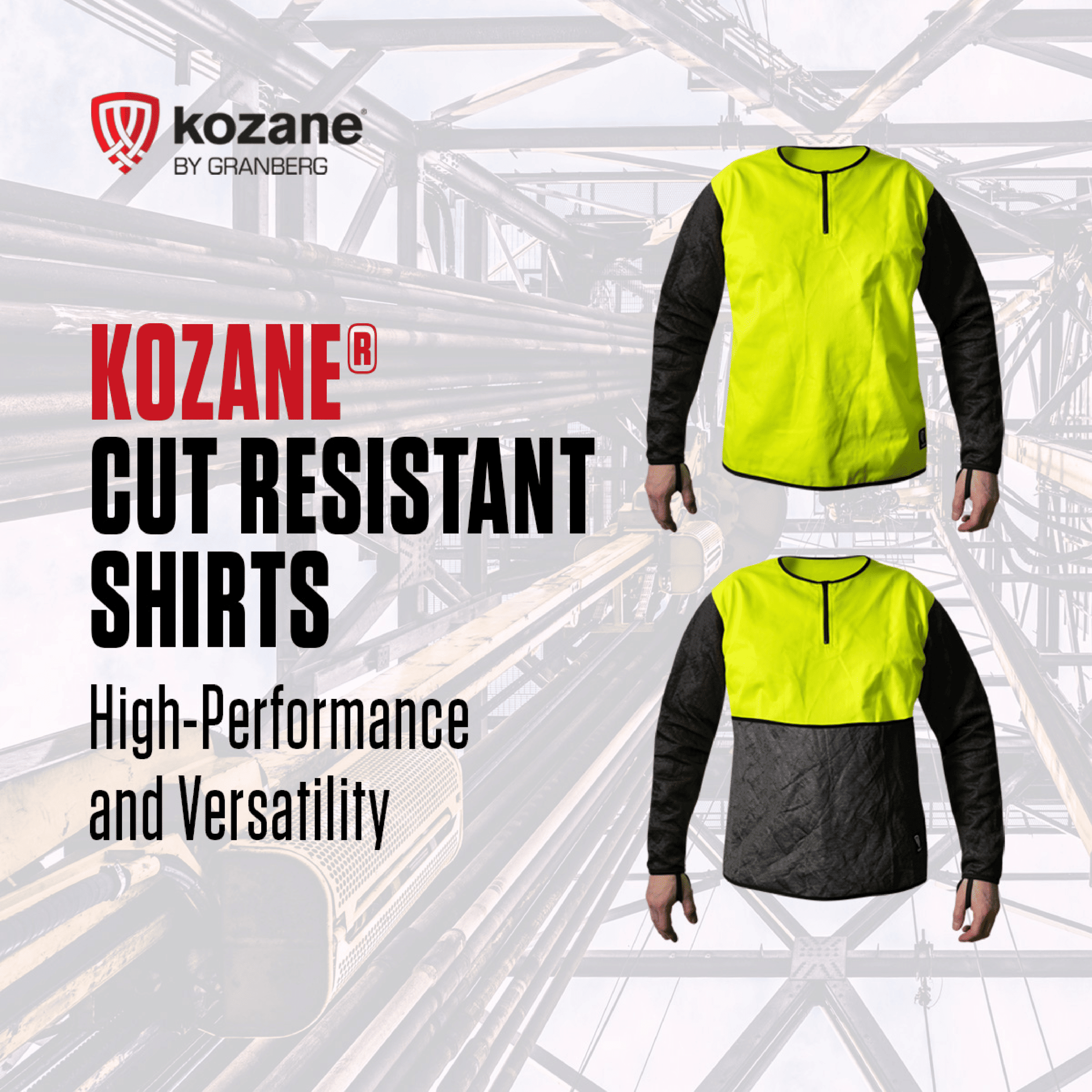

Kozane® Cut Resistant Shirts

High-Performance and Versatility

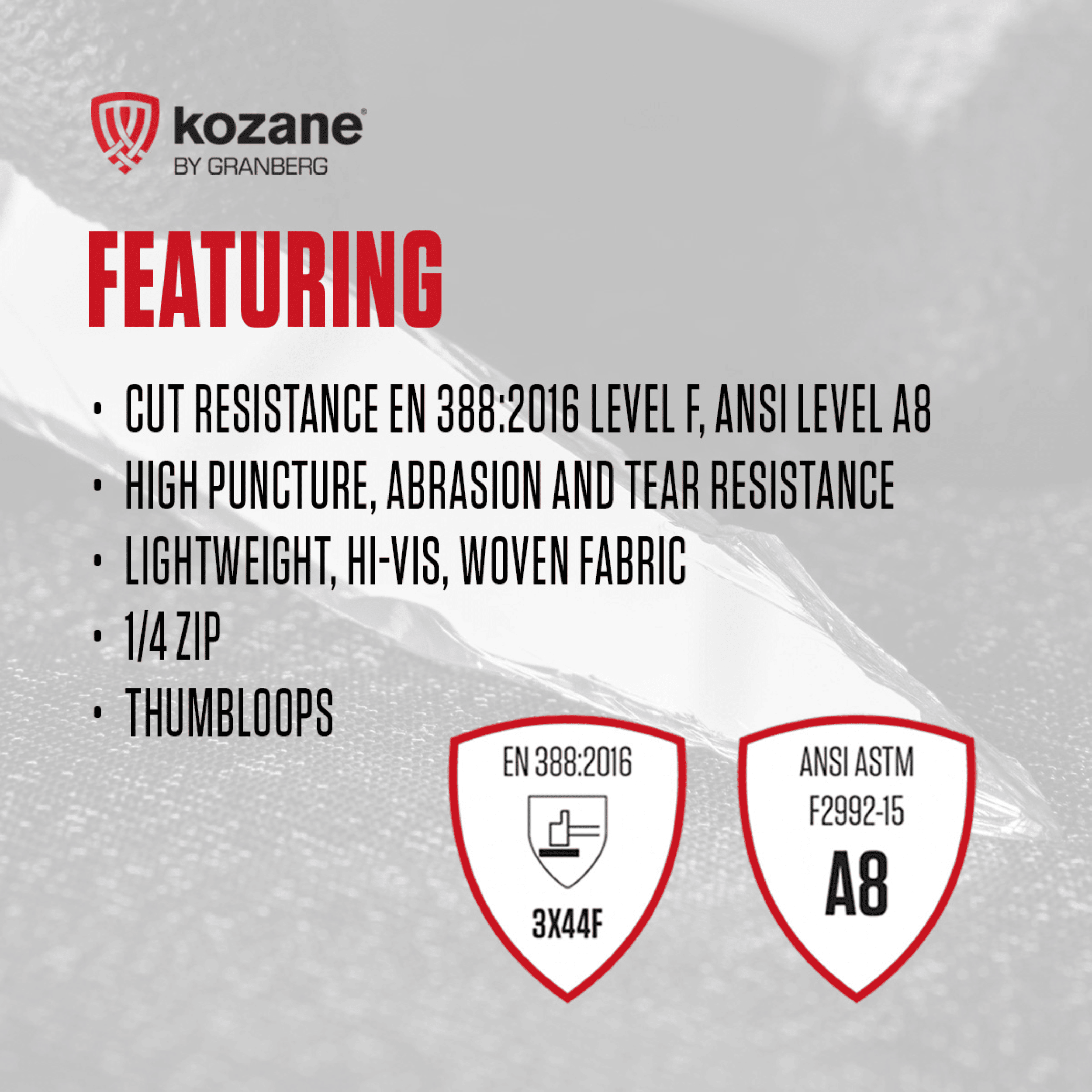

For those working in high-risk environments where sharp objects are a concern, reliable cut protection is essential. According to the widely recognised EN388:2016 European Standard, a minimum cut level E is suitable for protective garments used in industries such as automotive, pulp and paper, glass manufacturing, construction, recycling, metal fabrication, etc., where exposure to cuts, lacerations, and punctures is high and extreme. According to the American equivalent, ANSI, a cut resistance level of minimum A6 is recommended for such high-risk industries. Aside from providing maximum protection, cut-resistant shirts must be compliant with government and industry standards for workplace safety, but also offer essential comfort for the wearer, during hours of manual labour and repetitive tasks in dangerous environments.

At Kozane®, we understand that depending on the industry, there are certain hazards and threats workers are exposed to. We’ve learned that across different high-risk sectors and industries, often the arms are mostly at risk from lacerations. Our lightweight Cut Resistant Shirts offer unparalleled comfort and protection in the workplace, even in the harshest of working conditions, multitasking as a work uniform and PPE. Offering the highest cut resistance in combination with breathability and comfort for the wearer, Kozane® Cut Resistant Shirts are suitable for a variety of work environments where there is a risk of cuts and lacerations to the arms and/or the stomach area.

At Kozane®, we understand that depending on the industry, there are certain hazards and threats workers are exposed to. We’ve learned that across different high-risk sectors and industries, often the arms are mostly at risk from lacerations. Our lightweight Cut Resistant Shirts offer unparalleled comfort and protection in the workplace, even in the harshest of working conditions, multitasking as a work uniform and PPE. Offering the highest cut resistance in combination with breathability and comfort for the wearer, Kozane® Cut Resistant Shirts are suitable for a variety of work environments where there is a risk of cuts and lacerations to the arms and/or the stomach area.

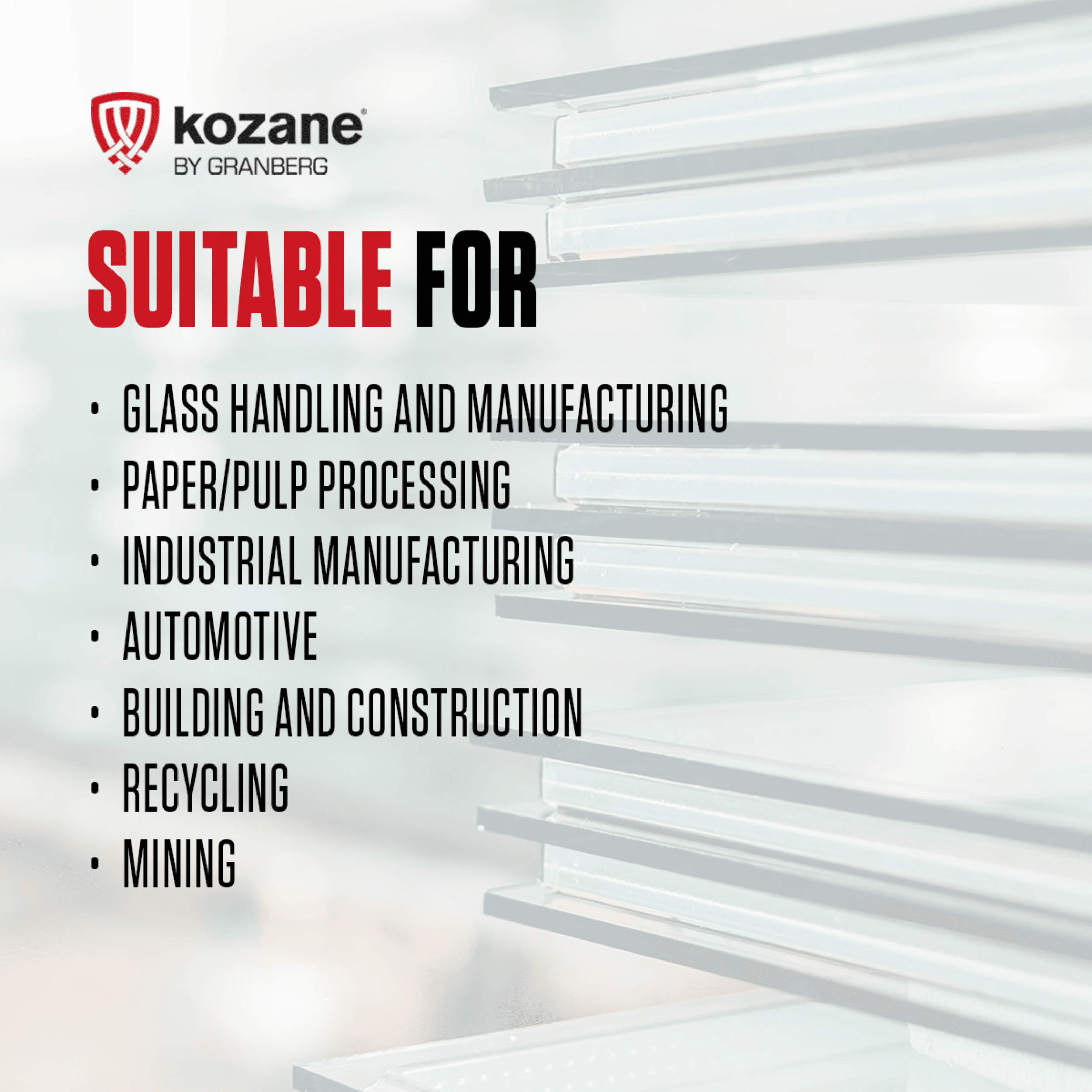

Automotive

Automotive workers are exposed to abundant hazardous elements from dangerous machinery, equipment, and harmful chemicals to handling sharp or abrasive materials. These workers who are exposed to various hazards every day and face constant manual handling, covering a broad spectrum of activities, and encompassing many repetitive or strenuous tasks, would benefit from wearing lightweight cut-resistant shirts, and avoiding heavy, cumbersome PPE.

Metal Fabrication

As many as a third of all injuries in the metal fabrication industry involve cuts, lacerations and punctures caused by sharp metals, thereby contributing to the ranking of cuts as the second most frequent workplace injury. Whether employees oversee cutting raw materials, or they are bending metal sheets to create the intended form or even down the assembly line of crimping and riveting, their arms and sometimes the abdomen area are mostly at risk from injuries caused by sharp tools or materials.

Construction

Topping the list of construction-related injuries are hazards in contact with sharp objects and materials or equipment leading to cuts, lacerations, and punctures. Lacerations to the arms are very most common and often the most detrimental injuries to workers on construction sites, however, laceration injuries can happen anytime a body part is close to sharp objects. A challenging aspect of the construction sector is that each site can be unique, with its own set of dangers and potential safety hazards. Unlike in a controlled working environment, construction job site conditions are constantly changing.

Mining

The mining industry is considered a very dangerous sector with one of the most hazardous working environments. According to a non-profit safety council in the US, the mining industry holds the second highest casualty rates. It is therefore crucial that workers wear quality personal protective equipment (PPE) to keep them safe while on the job, with the appropriate cut-resistant fabrics for mining workers. Mining industry workers face a lot of on-the-job risks and hazards depending on the specific task they are performing. In the recent report of the Occupational Safety and Health Administration, 40% of the injuries occur on the body. The Kozane® lightweight cut-resistant shirts can be worn in combination with our trousers, aprons, or chaps, depending on the activity.

Glass manufacturing

Manual handling is often unavoidable in the glass sector, and accidents can occur despite comprehensive safety measures and staff training. Workers can perform their tasks safely and comfortably when wearing our lightweight cut-resistant shirts, whether manufacturing flat glass or operating a bottling plant, tasks such as selecting and moving stock, laying materials on a bench for cutting, unloading glass sheets from containers and vehicles, or placing products in racks ready for dispatch.

Historically, most cut-resistant garments on the market are bulky, use heavy, non-breathable materials, can be expensive, and use problematic fibres, for example, glass fibre is harmful if ingested and can irritate the skin, and Kevlar fibres degrade with UV and moisture exposure.

Developed by our experienced R&D team, the Kozane® Extreme fabric offers the optimum combination of the highest cut resistance levels and wearability. The product of the multi-award-winning Norwegian company, Granberg AS, with over 60 years of experience in protecting workers facing challenging conditions, it is breathable and soft and designed for garment manufacturing across many different sectors.

Developed by our experienced R&D team, the Kozane® Extreme fabric offers the optimum combination of the highest cut resistance levels and wearability. The product of the multi-award-winning Norwegian company, Granberg AS, with over 60 years of experience in protecting workers facing challenging conditions, it is breathable and soft and designed for garment manufacturing across many different sectors.

Check out the full range of Kozane® Range of Protective Garments for more styles and information.

With the right PPE, you can avoid accidental injuries, keeping workers safe and saving your company both time and money.

If you are as passionate as we are about worker safety and would like to find out more about our lightweight cut-resistant shirts, including how they can be customized, contact KozaneⓇ’s dedicated representative, Eve Lamb, at +44 (0)7599 546 566 or reach out via email to eve.lamb@granberg.no.