Understanding Cut Resistance and Global Cut Standards

Cut resistance involves several aspects such as force, direction, blade sharpness, cut length and object flexibility. Different products apply depending on the type of cut risk and the environment they are likely to face. In recent years, the performance of cut-resistant fabrics has significantly improved due to new technologies backed-up by researched and development. They do not simply withstand slashing or cutting actions but also have various applications for mechanical protection to withstand the most challenging environments avoiding accidents and occupational hazards.

The two most common global standards

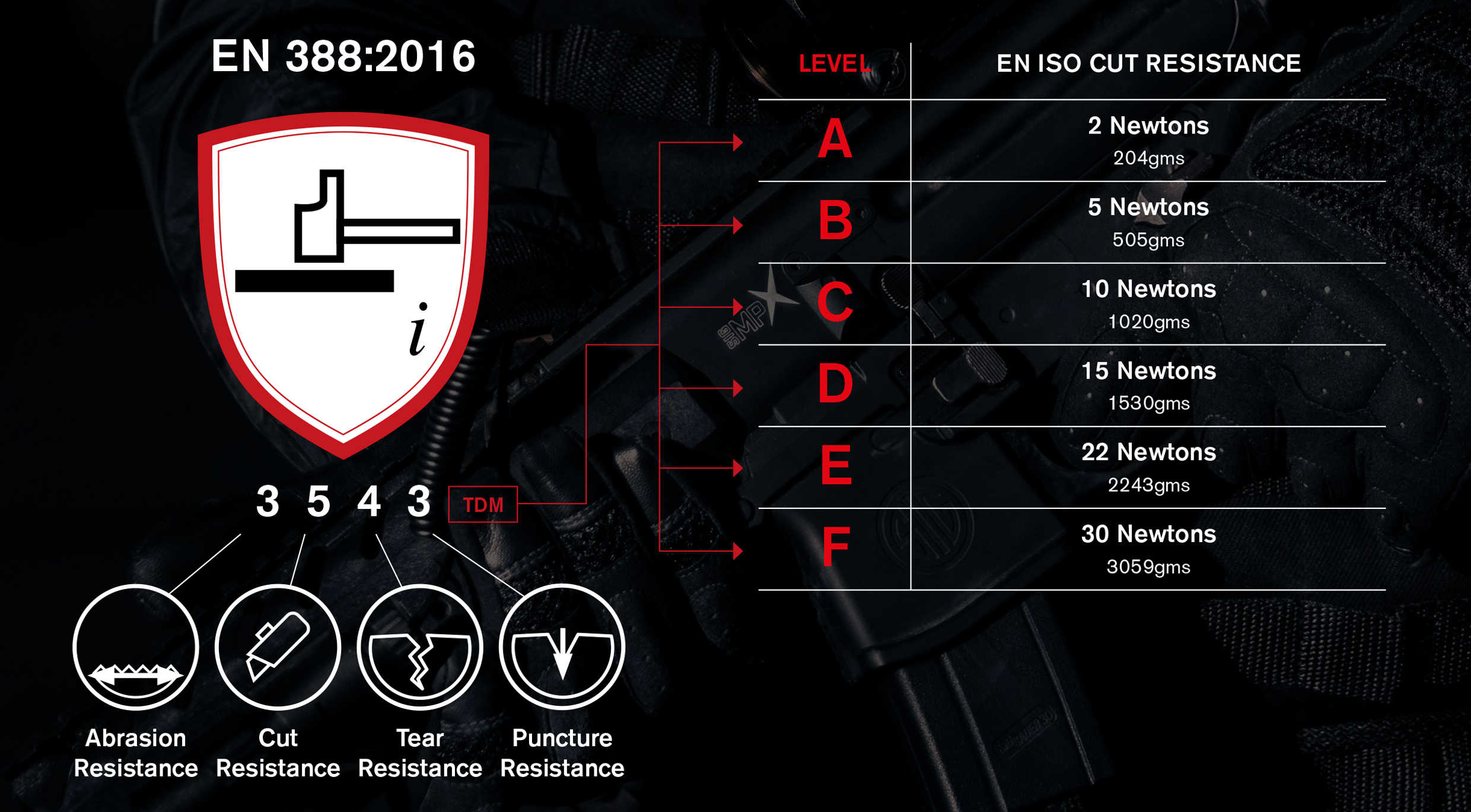

Testing the level of cut resistance utilises either the European cut resistance standard, EN 388:2016 which is also recognized across Canada, Asia, Australia, New Zealand and Latin America, or the American cut resistance standard, ANSI/ISEA 105.

Both standards use the same piece of test equipment – the Tomodynamometer or TDM – although the methods prescribed in each case (ASTM F2992 vs ISO 13997) are slightly different. Both standards updated in 2015-16 to improve transparency around cut performance and allow a more informed decision about the level of cut resistance required.

EN 388:2016 involves two tests for cut resistance – the coupe test (rotating blade) and ISO 13997 (TDM). The coupe test gives a cut score of 1-5 and applies for lower cut-resistant materials. The ISO 13997 test offers a more accurate result, implemented when the coupe test reveals a level 3 or above and results range from level A to F (F being the highest).

ANSI versus EN

The ANSI standard uses the ASTM F2992-15 (TDM) test, in which the sample receives five cuts with three different loads and an average results in a cut score of A1 to A9 (A9 being the highest).

Kozane® High-Performance Fabrics is a Granberg brand, and we are continuing our core tradition by committing to ensuring quality and safety as top priority. Our talented research and development team have engineered the Kozane® High-Performance Fabrics range to achieve high cut resistance while and offer high levels of abrasion, tear and puncture resistance. They are suitable for high-risk industries such as military, security, and law enforcement as well as manufacturing, food processing and sports.

Stay tuned for the launch of our newest innovation – Kozane® Supreme. A first for a knitted fabric of its kind, it offers the highest cut resistance according to EN 388:2016 – Cut level F, and an outstanding ANSI A9 cut score according to ANSI/ISEA 105. Kozane® Supreme also features the highest puncture, abrasion, and tear resistance.

For more information about the new Kozane® Supreme and our range, please contact our dedicated representative Eve Ichim on +44 7599 546 566 or send an email at: eve.ichim@granberg.no.