Understanding Cut Resistance and how it applies to PPE

When working in high-risk environments where sharp objects are a concern, reliable cut protection is essential. PPE manufacturers have to make sure they are using the correct cut-resistant fabrics. With so many available options on the market, how do you know what protection suits your workplace, or the right cut-resistant fabrics to use? Keep reading to find out about Kozane® cut-resistant fabrics and the global standards for cut resistance.

Knowing the level of cut resistance that is right for your work environment will help ensure your safety and protection. In doing so, understanding the levels of cut resistance for PPE and the global standards is paramount.

There are two prominent standards determining the cut resistance level. The European (EU) standard, EN 388:2016, and the American standard, ANSI/ISEA 105-2016. Both have their own testing methods to determine the level of protection for cut-resistant fabrics.

EN 388:2016

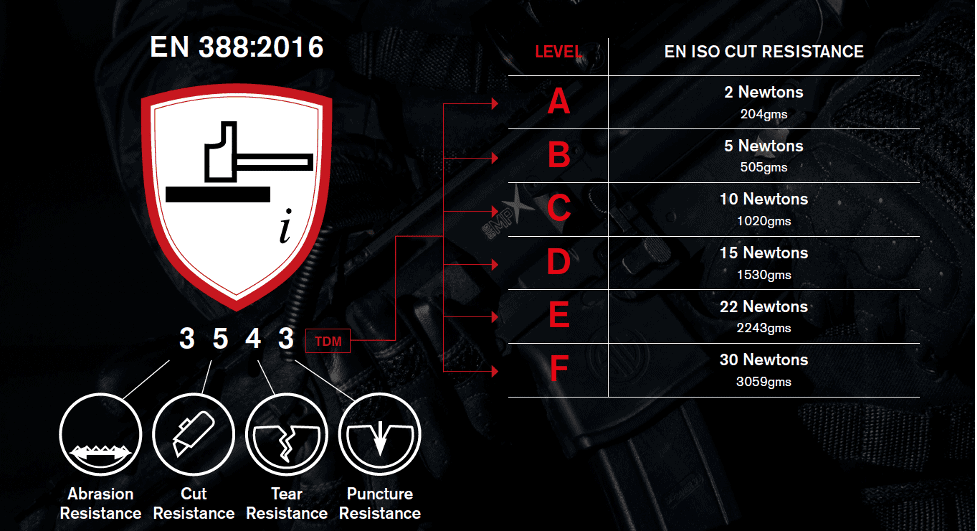

For the European Standard, EN 388:2016, the material undergoes testing with the coupe test (rotating blade) and ISO 13997 (Tomodynamometer or TDM). Lower cut-resistant materials use the coupe test with cut score results of 1-5. When the coupe test result is level 3, ISO 13997 achieves a more accurate result. The levels are in Newtons and the result range from level A to F (F as the highest). The more weight (in Newtons) required to cut through the material, the higher the result (level).

ANSI ASTM F2992-15

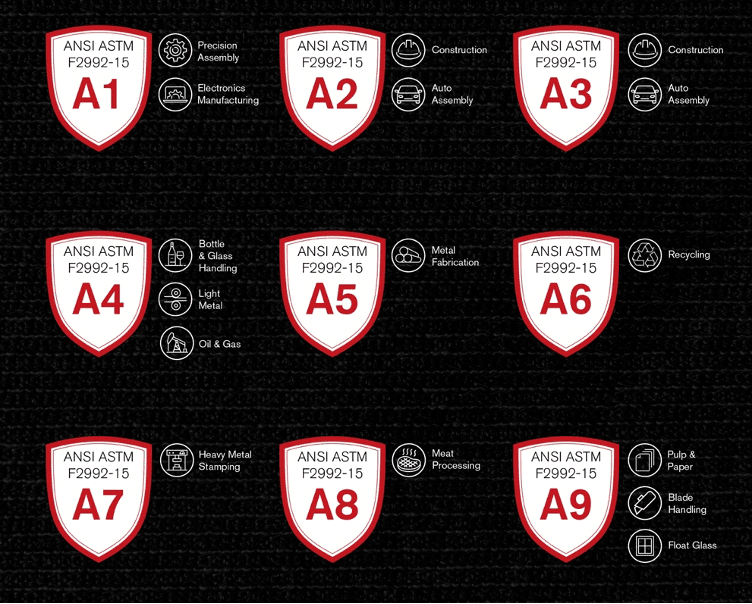

The ANSI standard uses the ASTM F2992-15 (TDM) test. A blade cuts the material five times with three loads, calculating the average. The pressure is measured in grams of force, resulting in a cut score of A1 to A9 (A9 is the highest).

It is necessary to know that these standards are not equivalent, although both use the same machine and testing methodologies. The scores come in different units of measurement, one in Newton (force) and another in grams (mass). A cut-resistant material that has achieved a Cut Level D cannot claim to be an ANSI Cut Level A4. Each must still undergo the test to determine its actual EU and American levels.

Levels of protection

The levels indicated by both standards will help determine the type of industry, hazards, and application a fabric or PPE garment is suitable for. For EN 388:2016, you can categorize it as low hazard exposure, moderate, and high or extreme.

Cut levels A to B – best for general-purpose material handling with low hazards to cuts and exposure to sharp edges.

Cut levels C to D – for the sector of logistics, warehousing, food preparation and packaging, and manufacturing with moderate cut hazards.

Cut levels E to F – for industries such as automotive, pulp paper, glass manufacturing, recycling, and metal fabrication where exposure to cuts, lacerations, and punctures is high and extreme.

As for the ANSI standard, PPE with cut resistance levels of A3 and below have applications where the cut risk is lower, such as assembly, warehouse work, and general handling. However, for applications where the risk of cuts and lacerations is higher and sometimes extreme, we recommend cut resistance level of minimum A5, for industries such as handling glass sheets, metal sheet fabrication, and glass manufacturing.

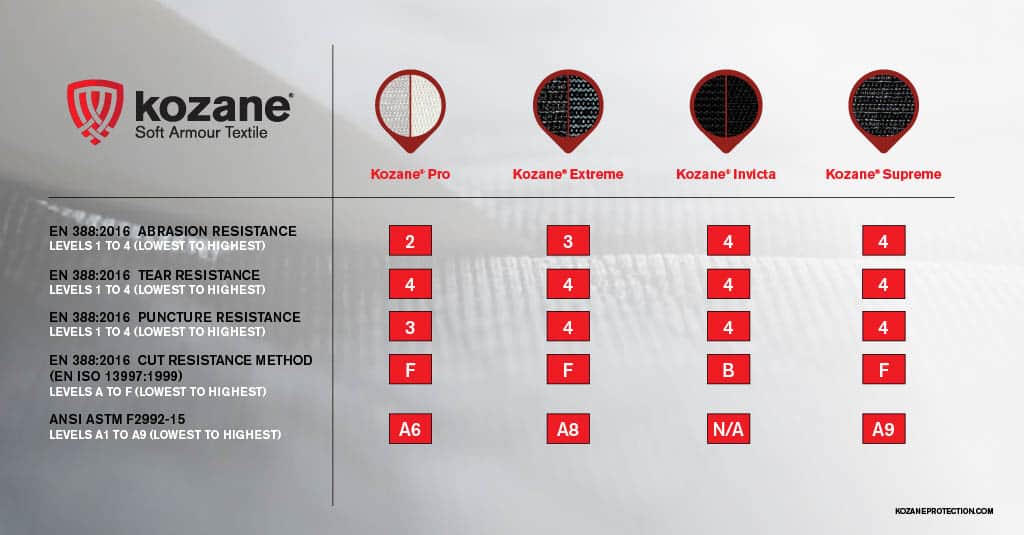

At Kozane® we understand the importance of not just having the right PPE. Ensuring it corresponds with the right level of protection needed for a particular work environment. Our high-performance fabrics are the product of a multi-award-winning Norwegian company, Granberg AS. We continue our core tradition by committing to ensure that quality and safety is always our top priority. We engineered and tested our fabrics to perform various applications suitable for multiple work environments.

Need advice about choosing the correct high-performance fabric for your PPE? Please contact the Kozane® representative Eve Ichim, Tel: +44 (0)7599 546 566 Email: eve.ichim@granberg.no